riteTime

Timesheet Entry & Labour Data Collection from riteSOFT.

riteTIME is a labour and machine time tracking system, with integration to Sage and Preactor for real time updates of the actual production versus the plan.

Utilising touch screen technology and barcoded data entry to ensure accuracy and ease of use on the shop floor.

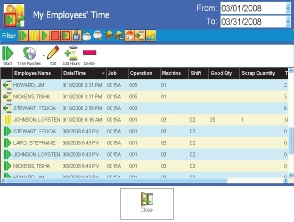

Data Collection and Timesheet Entry.

Users can enter their data at the place of work, using a touchscreen or a regular PC and mouse.

riteTIME is specifically designed to automate the tracking of jobs, work orders, scrap and maintenance items which have historically been tracked manually.

With the manufacturing process in mind, riteTIME provides real-

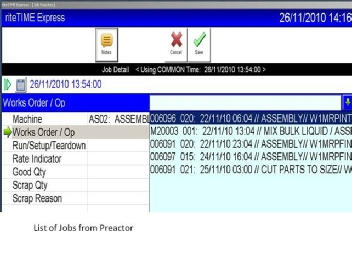

Preactor Integration

Preactor & riteTime have been integrated so that the operator can pick their next

job from a drop-

Do you want find out NOW or next MONDAY?

Benefits

|

●

|

A labour and machine time tracking system, with optional integration to Sage and Preactor.

|

|

●

|

Efficient, paperless collection of timesheet data.

|

|

●

|

Employees or supervisors clock people or machines onto jobs, so written timesheets are no longer needed.

|

|

●

|

Reconcile against your payroll data and track people's time as they move between jobs, departments or projects.

|

|

●

|

Calculate the actual costs of making your products and show variances against standard costs.

|

|

●

|

Get real-

|

|

●

|

Including scrap quantities, with reason codes.

|

|

●

|

Utilise simple touch-

|

Eliminate Double or Triple Entry

Streamline your process with riteTime.

How much time do your employees spend filling out production tickets / time sheets? How much time do you spend reviewing, correcting, and entering the data from these into other systems: accounting, payroll, ERP, scheduling?

riteTIME makes it easy for your staff to enter production data quickly and accurately on the shop floor. Because the labour data in riteTIME is easily extracted you can eliminate:

- Supervisors re-

entering production information into spreadsheets - Payroll entering hours-

worked data into the Payroll and HR systems - Accounting entering job costing information into ERP/Accounting systems

How much time are you wasting making duplicate entries?

riteTIME can help you devote more of your resources to production, not paperwork. And of course you can throw out your old time cards and clocks!

How will you get your people to use the system?

Simple! By giving them a user interface with non-intimidating touchscreen (or mouse)

simplicity.

riteTime >>

Learn more here on the riteSoft web site:

Integration

Preactor: Use the plan to display the next job for a machine in riteTIME. Send back

real time "mid-

Sage: Send job information to the shop floor terminals. View reports comparing standard and actual times and costs.

| Support |

| Preactor & Sage |

| Preactor AP |

| Preactor Support |