Preactor AP Advanced Planning

Master Production Scheduling & Rough Cut Capacity

The Preactor AP module is a planning system that is ideal for FMCG companies or other manufacturers who make to stock or are driven by customer forecasts and next day delivery requests.

Database scalability, Excel friendliness

Many companies use spreadsheets to generate their MPS. It’s a very user friendly experience.

But is it scalable and does it depend too much on the person who created the formulae?

Preactor AP utilises a SQL database and the well known capabilities of Preactor’s scheduling tools.

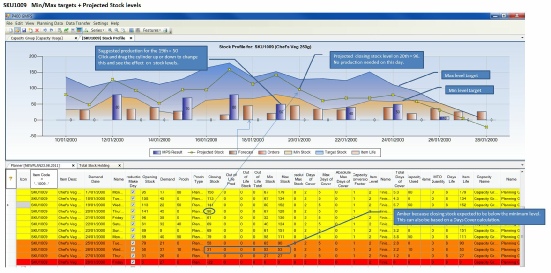

And you can quickly change the suggested production, by typing in the grid area OR by drag and drop on the graph elements!

Master Production Scheduling

At the top of the Demand Management tree sits MPS. It’s purpose is to propose, for finished goods items, a production plan that keeps the days cover of stock within satisfactory upper and lower limits.

Preactor AP calculates the required production for each period and charts the financial impact of holding finished stock.

Preactor’s long history of producing software for manufacturing underpins AP, providing rough cut capacity checks. This can smooth out the MPS suggestions so that the factory is not overloaded by an MPS that is trying to reach the perfect stock position, with no consideration of capacity. A firm plan period based on an underlying Preactor AS scheduling system can also be included.

Rough Cut Capacity

<< Projected stock for one SKU

Capacity chart >>

| Support |

| Preactor & Sage |

| Preactor AP |

| Preactor Support |